| Sehen Sie mehr Fotos in der BILDERGALERIE

|

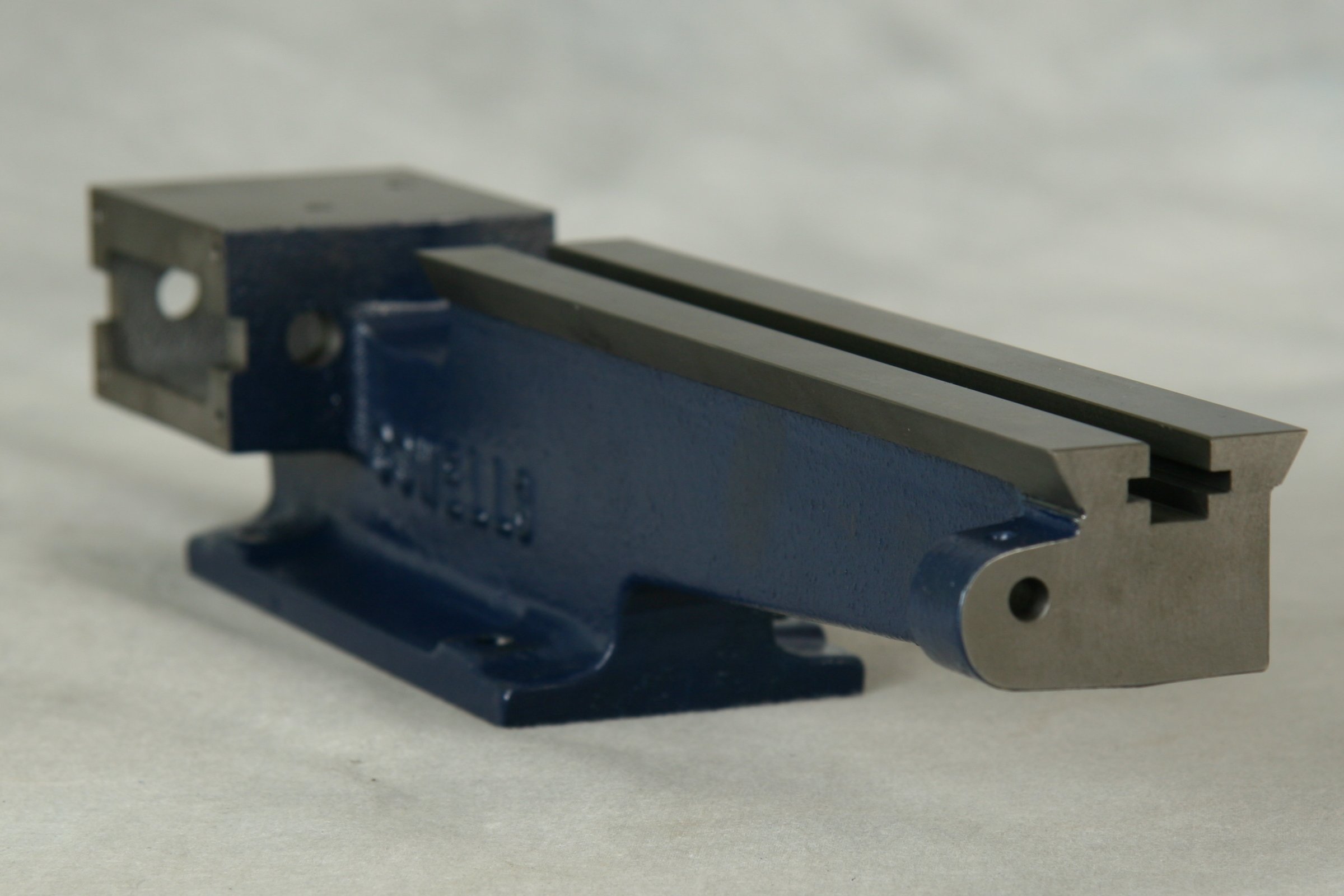

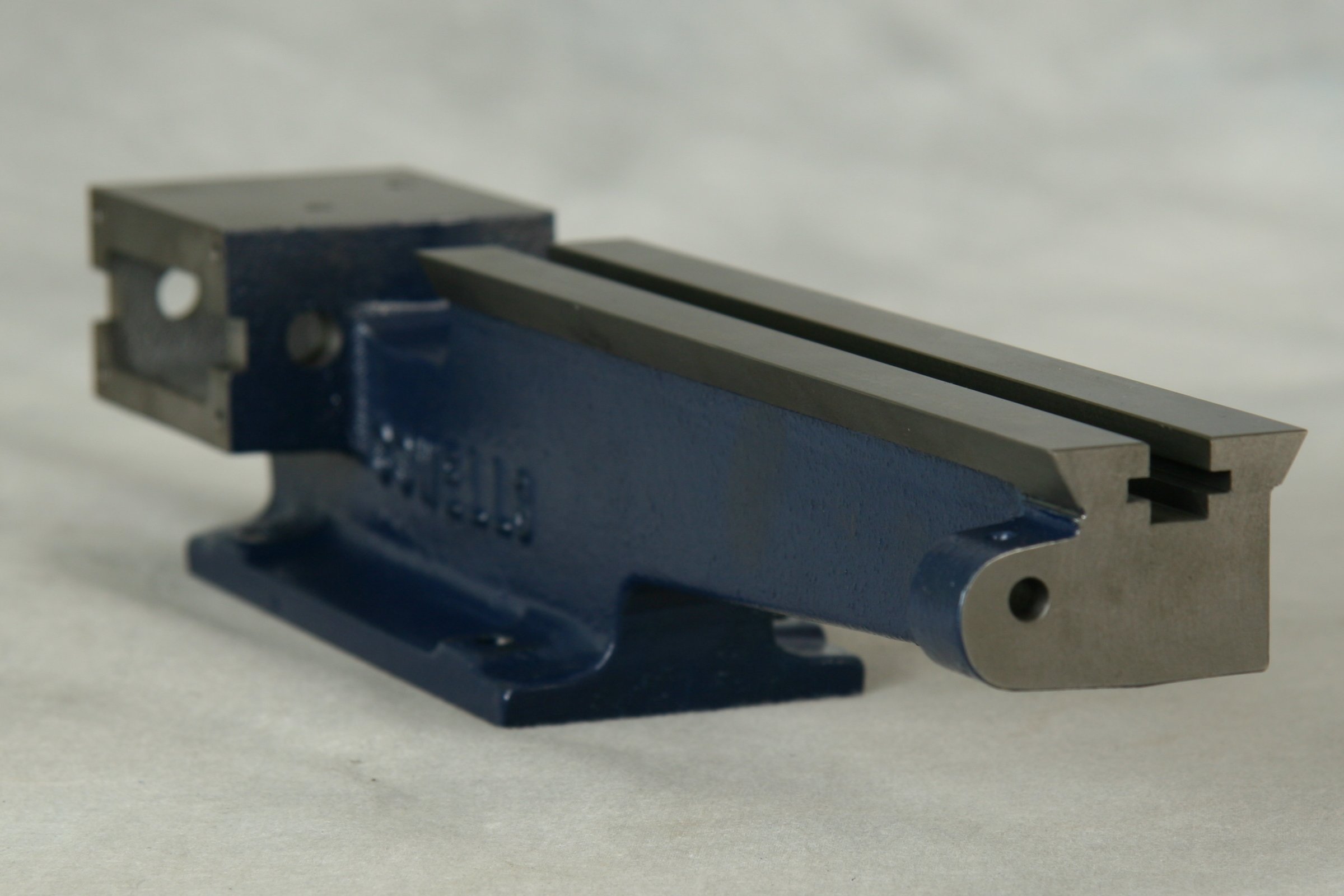

Lathe Bed

A one piece massive iron casting of cantilever

form incorporating auto-traverse clutch box. The bed is dovetail in

form and ground on all faces. A central Tee-slot provides a positive

and accurate location of the tailstock. A gap in the bed allows for

the swinging of a clock wheel up to a diameter of 120mm. |

Solid cast iron ensures rigidity

Solid cast iron ensures rigidity

|

Saddle and Slides

The cast iron saddle can be rapidly or sensitively

traversed via the saddle lever feed (a leadscrew can be fitted if preferred).

A long tee slotted cast iron crosslide permits the mounting of accessories

such as the Vertical Milling Slide(RG55), Milling Head (RG85), Jacot Unit

(RG59) and Roller Filing Rest (RG53) and may also be used as a table for

in line boring. The crosslide has an etched angular scale 45° - 0 -

45° and carries the swivelling Topslide to permit taper turning. A quick

change height adjustable tool holder is fitted. All slides are fitted with

full length adjustable gib strips. Handwheels are stainless steel and are

fitted with very accurate computer laser etched reset-to-zero calibration

dials. The clearly marked dials are graduated in 50 increments of 0.02mm.

The choice of Saddle Lever Feed or Manual Feed Leadscrew is a matter of

preference; there is no price differential between either option. Cowells

can supply either option as a retro-fit if required.

|

|

Tailstock

The tailstock is cast iron, bored and honed to accommodate

the hardened ground steel barrel. The barrel accepts the 8mm horological

collet, which is secured in the conventional manner with a draw-in bar.

The barrel is lever fed to facilitate high sensitivity drilling. Locking

handles are fitted to both body and barrel. The tailstock may be off-set

for the turning of long and shallow tapers.

Tailstock lever feed aids sensitive drilling. The image to the right is

an arbor being drilled whilst supported in the (RG59) Jacot Cone for re-pivoting.

|

|

Headstock

The cast iron headstock incorporates opposed

cone phosphor bronze bearings front and rear with a hardened and ground

steel cone running in the rear bearing.A fine threaded adjuster nut

fitted to the rear of the headstock spindle acts upon the steel cone

for the elimination of spindle end-float. This high quality bearing

arrangement ensures longevity and spindle concentricity and eliminates

'tool chatter' and eccentricity so often found in machines fitted

with small inferior ball bearings. The headstock spindle is hardened

and ground and directly accepts 8mm collets and tooling. The typical

T.I.R. (total indicated run-out) being 0.005mm. The spindle also incorporates

a plain diameter and back face with 3 x threaded holes for the mounting

of 3-Jaw Chuck(RG9), 4-Jaw Chuck (RG10) and Faceplate (RG28) via the

Chuck Adaptor (G13) This method of fixing the 3-jaw chuck etc. ensures

accuracy and rigidity which can often be a problem associated with

8mm collet lathes. The headstock pulley has 60 index holes and a spring

steel detent arm providing a direct headstock spindle indexing facility.

The headstock is fitted with spring cap oilers to both bearings incorporating

felt pads for the retention of lubricant.

|

The headstock spindle has a 60 division indexing

facility

The headstock spindle has a 60 division indexing

facility

|

Accuracy

Each lathe undergoes a meticulous examination

of its accuracy prior to delivery. Eight main tests are recorded on

an Engineers Test Certificate. The certificate carries the lathe's

serial number, is signed and dated and represents Cowells accuracy

guarantee. Typical overall accuracy is 0.005mm. |

Test Certificate

Test Certificate

Accuracy Guarantee

|